Indentations from Particles Causes and Countermeasures

2021-04-20

-

How:

- Solid contaminants can be introduced into a bearing via the seals or lubricant. After constant rotation, particles will be pressed into raceways and causes indentation.

-

Possible source of particles:

- Dust and metal debris exist in bearing assembly or operating environment.

-

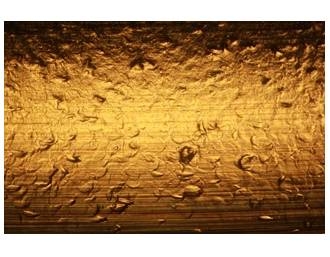

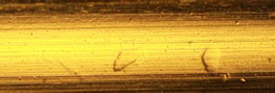

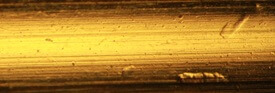

Indentations resulting from particles:

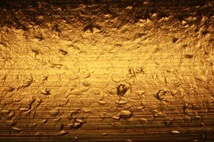

Indentations by soft metal debris

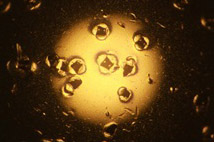

Indentations by hardened steel debris

-

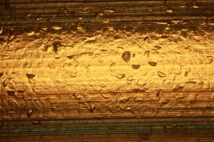

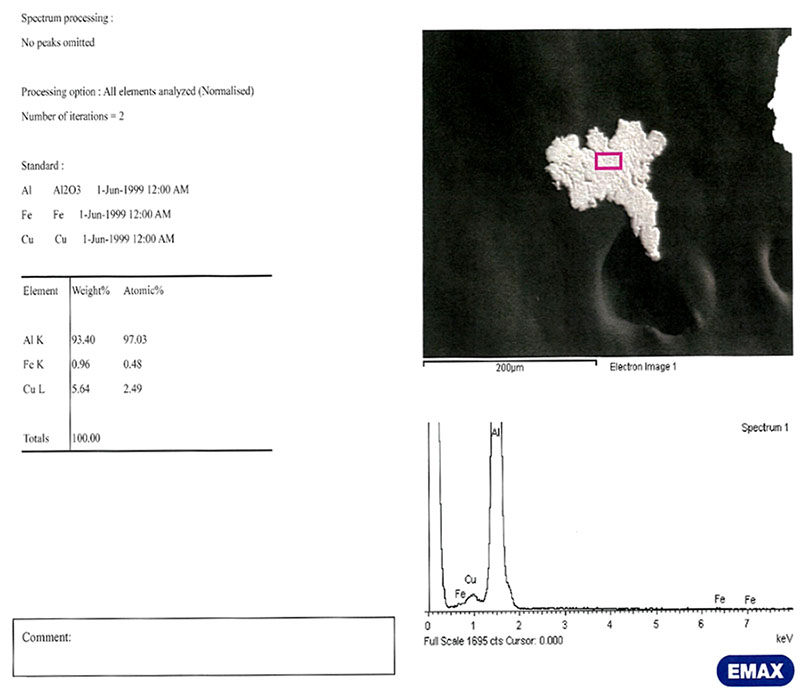

Example of SEM/EDS elemental analysis:

-

Countermeasures:

- 1. Improve the cleanliness of entire environment to reduce the possibility of particle intrusion.

- 2. Use adequate sealing to protect the bearing.