Four TPI Core Technologies in Bicycle Application

TPI bearings are well-known and widely used in bicycle industry. For example, the hubs and wheelsets of Rio 2016 Olympic championship bicycle was supplied by a Swiss high-end bicycle component manufacturer who has long term cooperation with TPI. TPI has four core technologies in bicycle industry and they are as follows:

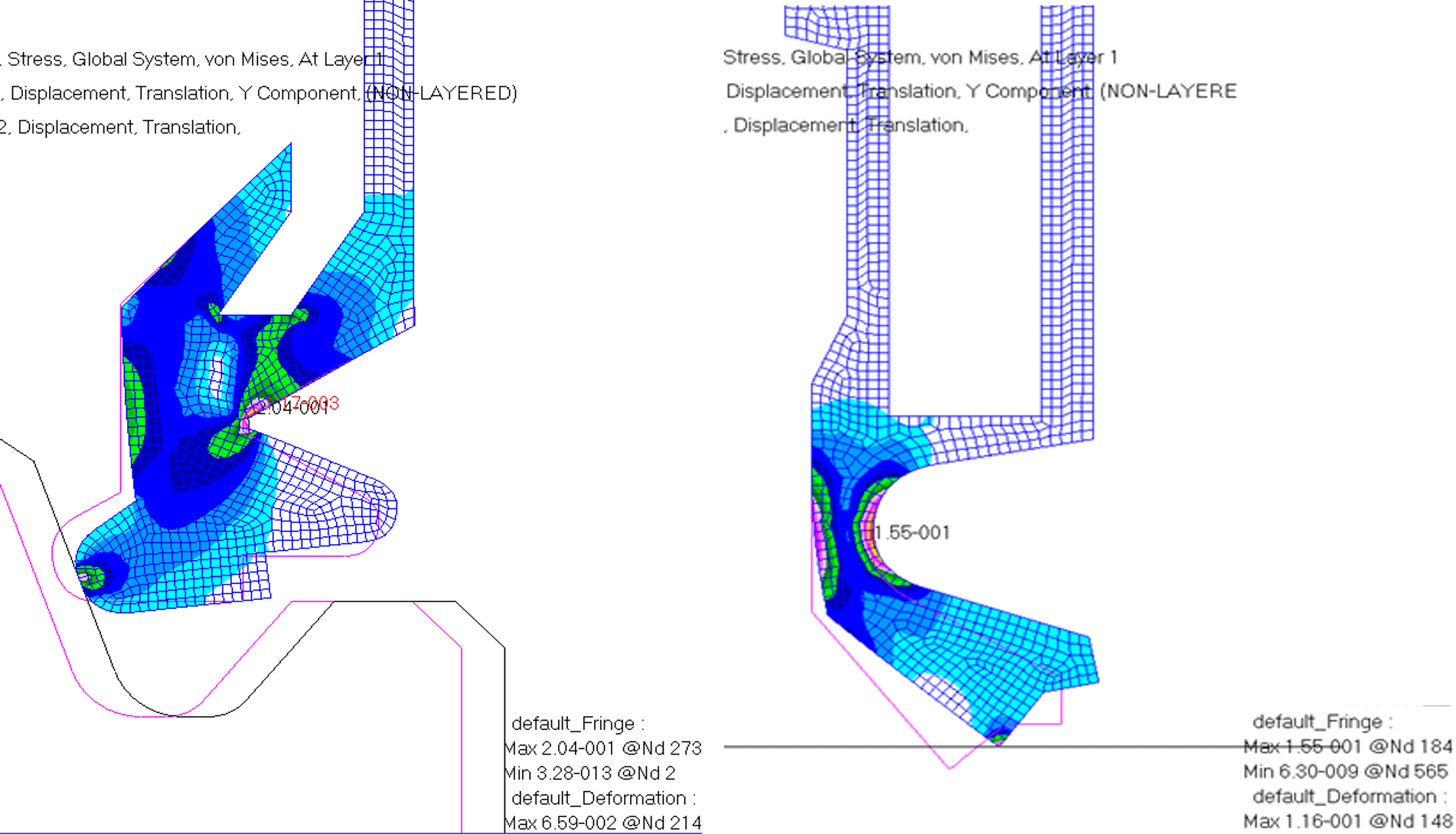

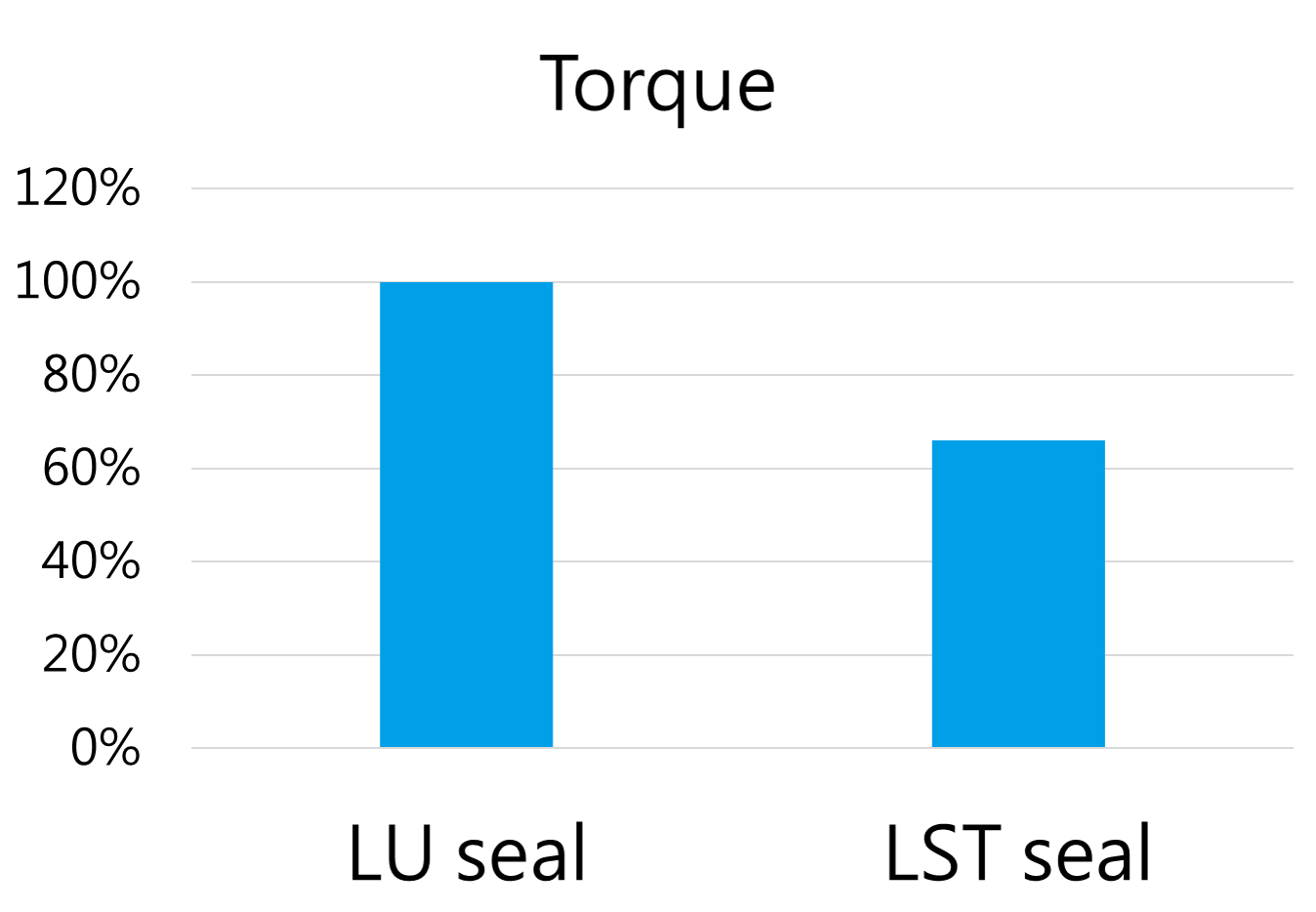

TPI seal simulation structure obtained through finite element analysis not only retains the original dust and water resistance, but is also proven to reduce torque by 33%.

(Please refer to Ball Bearings For Bike Wheel Hubs)

2. The ultimate in lightweight performance

All ceramic bearings for bicycle are only 75% of the weight of a standard bearing, which can help racers get ahead in a exteme competition!

(Please refer to Ball Bearings For Bike Wheel Hubs)

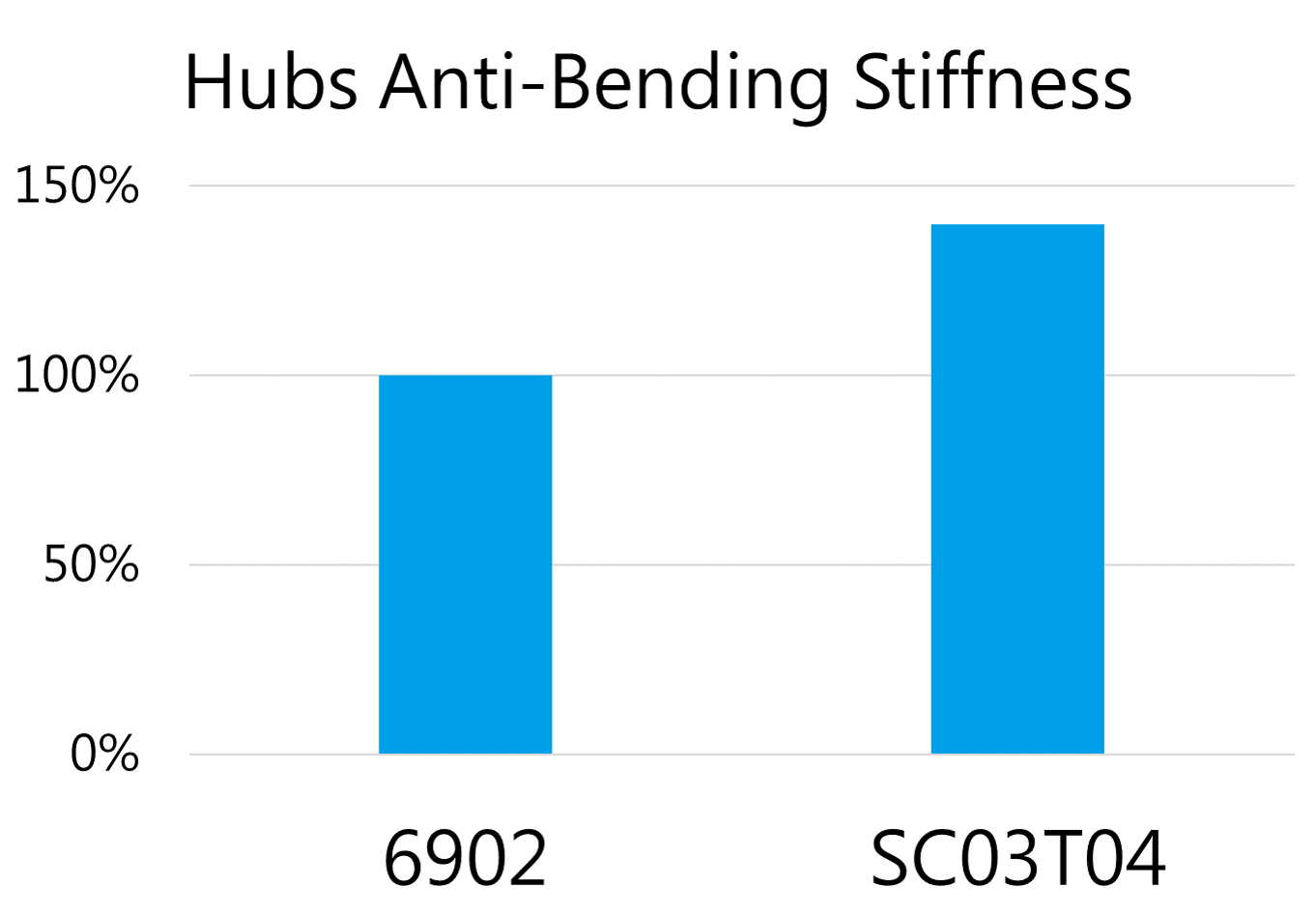

3. Improved bending strength

TPI has developed custom bearings by adjusting the internal design of bearings to increase the bending strength of bicycle hub mechanisms by more than 40%.

4. Conforms to European EN14764 standard

TPI bicycle hub bearings have passed the high strength impact test; the design and test conditions are in accordance with European EN14764 standard, which enables the overall bicycle mechanism to run safely and smoothly even under extreme bumpy road conditions.