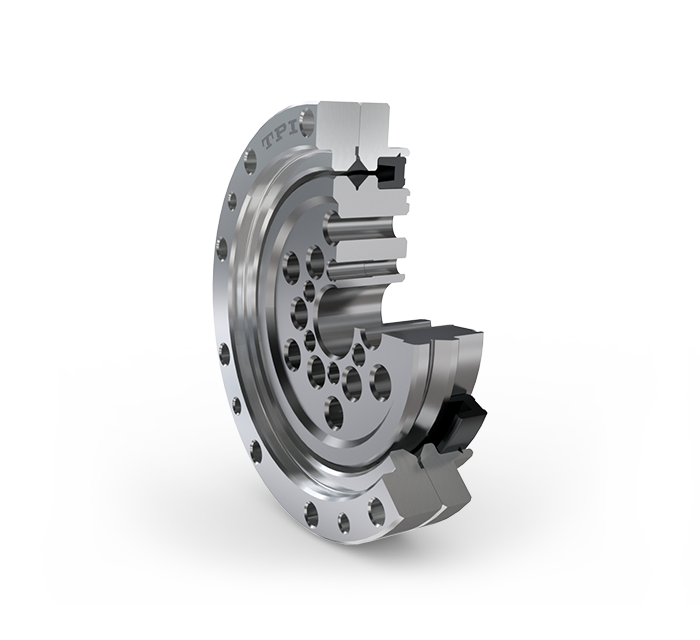

Cross roller bearing for the strainwave drive is structured by a two-pieces outer ring and one-piece inner ring with full roller in the raceways. The rollers are in linear contact with the 90° V groove raceways. The elastic deformation caused by the load is extremely small, so a single cross roller bearing can bear loads in all directions such as axial load, radial load and even moment. At the same time, the two-piece structure of outer ring is fixed together by bolts to avoid separation during installation or transportation and the operation is rather simple.

Cross roller bearing for the strainwave drive is composed of inner ring, outer ring, roller, seal and O- ring. The inner and outer rings have mounting holes on it and do not require fixed flanges nor supports and it is easy to install. This kind of bearings have high rigidity, high rotation precision and high capacity of combined loads. Hence, they are most suitable for applications of strainwave drive in industrial robot arms.